This isn’t precisely my first time dropping a container filled with Chinese language electrical autos within the yard and cracking it open with childlike glee. However it’s doubtless some of the distinctive experiences I’ve had to this point doing this, revealing inside a fleet of battery-powered Chinese language electrical mini-excavators and various equipment.

In the event you’ve adopted my escapades in my articles and movies for any period of time, you’ll know that is just about par for the course for me. I’m the man who imported that viral $2,000 Chinese language electrical mini-truck that netted tens of tens of millions of views across the web. I adopted that up with electrical boats and electrical tractors and all kinds of different enjoyable EVs from the world’s largest and most controversial electrical automobile market.

This time although, issues are getting severe as I get to work. Or, at the least work-related autos, as my newest import is a pile of electrical mini-excavators. So buckle up and be a part of me for the journey! And if you wish to see the method in full transferring footage, take a look at my enjoyable container unboxing video right here to get this expertise first hand.

In case you’re questioning how I obtained right here, it began with a necessity for an electrical wheel loader – a kind of articulating tractor that’s helpful for a variety of land managing duties like digging, loading, hauling, trenching, towing, and extra.

My dad and mom stay on a little bit of land in Florida and wanted just a few machines to assist sustain with chores across the property. They don’t want an enormous tractor, however some modest machines can be an enormous assist.

Because it seems, there really are just a few smaller articulated wheel loaders accessible for these kind of homesteaders and landowners – of us who don’t actually need a $50,000 diesel Bobcat such as you’d see on a contractor’s job website.

Nevertheless, the household didn’t actually desire a diesel machine. With the appearance of electrical alternate options, some great benefits of decrease working prices, safer working surroundings, diminished upkeep, and quieter/extra peaceable operation had been too exhausting to cross up. Our household has an electrical mini-truck and an electrical UTV, each of that are main work autos for us, and the expertise has pushed house simply how a lot nicer it’s to personal and function electrical alternate options of widespread work autos.

The issue is that in terms of electrical tractor loaders and electrical excavators, there simply aren’t many choices. Almost every little thing out there may be diesel. With out discovering any choices for such machines within the US, I went to the world’s largest electrical automobile maker: China. There I discovered a number of choices that had been step in the fitting course, however weren’t fairly prepared for prime time of their present type. With start line, I labored with a manufacturing facility that I appreciated to enhance the machines for North American operators.

After making quite a few security, high quality, and ergonomic enhancements to the gear, the machines grew to become the primary NESHER electrical loaders in a rising lineup. Creating right into a small enterprise run by my father and me, we’ve now been in a position to rent a few workers and have since shipped electrical machines all around the US.

The subsequent logical step in rising was to develop into devoted mini-excavators, which might dig deeper and do extra than simply the excavator attachment accessible on the NESHER L880 and NESHER L1400 loaders. So I repeated the method however for excavators this time, working with an appropriate manufacturing facility to enhance their machines to my perfect design meant to raised serve North American customers.

Having now gone by this container importing course of many occasions over the past 18 months or so, this time I assumed I’d deliver you guys alongside on the method of cracking one in every of these open.

To start with, any one in every of these containers takes months to arrange. It begins with working with the manufacturing facility designers and engineers, then negotiating pricing, fronting the manufacturing, coping with inevitable manufacturing delays, high quality inspections earlier than transport, reserving sea freight, working by customs and dealing with tariffs, organising incoming freight, and at last touchdown the container at the doorstep.

It’s an extended and arduous course of with every step filled with complications, however having completed this with a dozen or so containers at this level, it’s beginning to grow to be simpler and smoother.

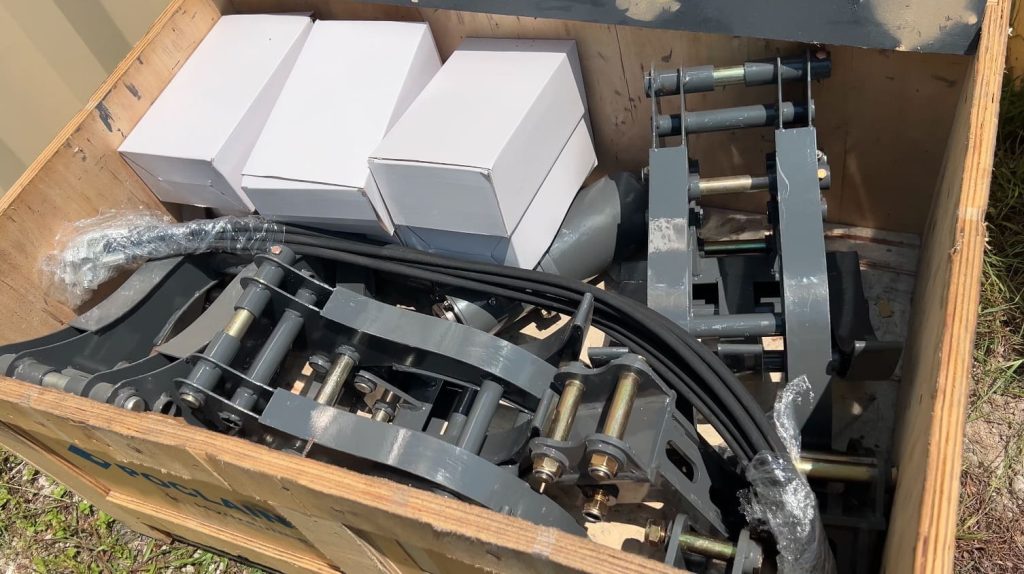

When the container lastly arrives after these many months of labor, the true enjoyable begins. I cracked this one open and set to work unloading the crates of mini-excavator attachments, corresponding to grapples, augers, ripper enamel, varied buckets sizes, rock hammers, and many others.

Subsequent got here the machines themselves. I all the time be sure that my factories bundle my machines additional nicely. It’s not as a lot the lengthy ocean journey I’m frightened about, which is comparatively light. Moderately, the primary and previous couple of hundred miles on the again of a truck chassis can bounce issues round extra. We use a spiderweb of strapping and a small military of ratchets to make sure each machine and attachment is secure and safe for the journey.

They’re every unloaded down the ramps and undergo an preliminary fast inspection on the lookout for any apparent points, like issues with the hydraulics or tracks, then pushed off to staging. As soon as all the machines are out and the container is cleared out, the extra intensive inspections start. Every machine is put by just a few hours of labor to suss out any potential points that had been missed on the manufacturing facility. Often this turns up one thing small, however thorough high quality inspections on the manufacturing facility imply that any actual points get caught earlier than they arrive stateside.

I’d be mendacity if I mentioned the inspection course of isn’t enjoyable, as a result of it principally means we get to mess around with all the features. And there’s one thing about digging holes with small-format heavy gear that simply brings out the internal youngster in you.

These are pretty small machines – the NESHER NX2500 mannequin title hints on the 2,500 lb (1.1 metric ton) weight of the mini-excavator. With a 5.5-foot (167 cm) digging depth, they’re nice for duties corresponding to landscaping jobs like tree planting, utility work like trench digging, materials dealing with like loading and unloading gravel, logs, and many others., and even gentle demolition work. They’re particularly helpful for indoor demolition and renovation jobs, since their zero-emission operation signifies that operators don’t need to run an extended exhaust hose to pipe out the toxic diesel exhaust or threat the well being of anybody within the constructing.

Nevertheless, the small measurement of the machines signifies that they aren’t actually meant for main jobs. You might dig a pond, nevertheless it’d take a reasonably darn very long time.

To provide you an instance, just a few days in the past I dug a few holes for some palm timber we’ll be including to the property, and the cost on the machine dropped by 2%. That doesn’t essentially imply it will likely be a linear drop and you could dig 100 holes on a cost, nevertheless it’s a tough approximation.

With a 48V 200Ah Li-ion battery, the 9.6 kWh battery is sufficiently massive for as much as 5-6 hours of light-duty operation, although digging by dense materials like clay or rocky terrain will cut back the run time. Recharging takes round 7 hours through a 120V wall outlet with the included charger.

Once more, this isn’t meant for an 8-hour shift on a job website. These are machines largely meant for landowners and homesteaders who typically have digging duties however don’t need to repeatedly lease a machine – not that you would discover an electrical mini-excavator to lease, anyway. Critically, give it a strive. If you wish to purchase or lease an electrical mini-excavator within the US, there merely aren’t any choices. They don’t exist. Or at the least, they didn’t.

There are just a few main firms which have begun producing them in very restricted numbers, corresponding to JCB, Bobcat, and many others. However they’re largely unobtanium, solely accessible to contractors, and carry pricetags approaching and exceeding six figures.

Widespread questions in regards to the electrical mini-excavators

The most typical questions I get on these are run time and price. With the 6-hour reply out of the way in which, that leaves pricing. To border this reply, it’s vital to grasp what costs appear to be on this business. There are VERY few sources for electrical mini-excavators anyplace within the Western World. The JCB 19C-1E is without doubt one of the few choices on the market. Conventional heavy gear firms don’t publicly share costs. You need to soar by hoops of JCB gross sales reps earlier than they lastly let you know that could be a practically US $100,000 machine.

However that machine additionally weighs round 1,500 lb greater than the NESHER NX2500. A better comparability can be the Bobcat E10e, which is roughly the identical measurement and spec because the NESHER NX2500. Once more, it takes loads of digging (no pun meant), however in the end you’ll discover that it’s priced at round US $60,000.

By comparability, the NESHER NX2500 is priced at US $19,600.

This isn’t to say that these machines are straight comparable, however they do have comparable specs and carry out comparable duties. Bobcat and JCB are actually bigger firms, however they cater to industrial customers. The NX2500, alternatively, lastly brings the aptitude of electrical mini-excavators to extra common Joes and small companies that may’t afford a $60k or $100k piece of kit.

One other widespread query I get when individuals hear I import loads of these kind of issues is “do you get to maintain the container?”

Typically, sure. However it’s not as a lot that I get to maintain and extra that I had to purchase it upfront. That is what is called one-tripper. Which means it’s a new transport container, and that is its first journey throughout the ocean.

On this case, I purchased the container so I might maintain it and use it as storage – principally an excellent sturdy and locking shed. You may need seen my article about turning a transport container into a solar-powered charging shed full with air con. That’s one of many good issues about selecting to purchase a one-tripper container, you may get very inventive with them.

Nevertheless, most of my imports are completed utilizing the transport line containers. These are basically borrowed from the container traces. Maersk or MSC or the opposite massive names lend you a transport container as a part of the worth of transport with them, you fill it in China, empty it within the US, after which it goes again to the port for a lot of extra journeys in its future. That’s the commonest and economical option to do it, however getting just a few transport containers of your individual isn’t a nasty factor both, when you have the house.

The final query that I typically hear is solely, “Why electrical?”

I get it, many old-school operators are of the “diesel or die” selection. The issue is, generally you get each. That diesel exhaust is a carcinogen. And in contrast to bigger excavators with enclosed cabs and higher exhaust manifold designs, most diesel-powered open-cab mini-excavators outcome within the operator’s face being situated a mere 2-3 ft from a diesel exhaust pipe. That’s not how I need to spend my digging hours and I wouldn’t want it upon anybody else.

Then you must add on prime of that the sound of an unisolated engine working inches beneath your thighs, the vibrations of that engine, the prolonged repairs and upkeep of an engine with a whole lot of transferring elements, and the trouble of winterizing or different additional steps that required to maintain such machines in good working order.

There’s a motive an influence drill has a battery and an electrical motor as a substitute of a small gasoline engine, although such engines are broadly accessible for mannequin constructing. Electrical instruments are merely nicer and extra handy to personal and function. Certain, 30 years in the past we didn’t have the type of motor and battery expertise to make electrical development gear a viable different. However now we do, and these machines are proof of it.

Are they dearer than a no-name diesel-powered Chinese language mini-excavator purchased at public sale for $5,200? Certain. However they’re additionally cheaper to function, longer lasting, safer, and extra snug, and are available backed by a US distributor with service and help, together with a neighborhood stock of spare elements. Electrical won’t be for everybody, however it’s for me, and now I’ve seen how it’s for a lot of others as nicely.

That is unlikely to be the final time I import one thing enjoyable and fascinating from China, although it actually is the final one with out new tariffs that had been not too long ago imposed. Like all companies, we’ll be analyzing the influence of the brand new tariffs on our personal working prices, and sadly, we might have to boost costs on these machines as our prices rise.

However since loads of what I usher in is for private use (and I’ve obtained extra enjoyable EVs already within the works!), that’s largely an issue for me to cope with.

I’m wanting ahead to sharing the following enjoyable EVs I get my fingers on. Till then, I’ll have these fingers busy digging!

FTC: We use earnings incomes auto affiliate hyperlinks. Extra.